Printed circuit boards. We love them because they can make amplifier production faster, easier and consistent. We hate them because if you are not careful you can burn up a circuit trace making a simple component tweak a repair job…yay.

Printed circuit boards. We love them because they can make amplifier production faster, easier and consistent. We hate them because if you are not careful you can burn up a circuit trace making a simple component tweak a repair job…yay.

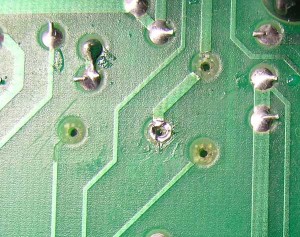

I have found over the years that if you are going to repair or tweak and amp with a printed circuit board (pcb) you should follow a couple guidelines. First make sure you set the heat of the soldering iron only as hot as you need. This almost goes without saying but important to know. Using excessive heat can destroy the thin, flimsy modern circuit traces. Some of the older amps have much heavier traces which can withstand more heat. So set your iron accordingly.

Second is you want to heat the solder joint, solder your component and get the iron off the part as fast as possible. You have to make sure you have a good, solid solder joint in the end but you do not want to linger there with the iron.

Third thing you can do is use what are called heat sinks. Basically the type of heat sink I’m talking about is a little clip type of gizmo that clips to a component that you are soldering. The heat sink keeps the component from overheating. You can use these on nearby components to help dissipate the heat a bit faster after you have made your solder connection on the pcb.

The trick is to be careful of the amount of heat to get the job done and the duration of the heat applied to the solder joint. If you follow these simple guidelines they will help you from ruining a circuit trace. I suggest that if you are going to attempt a repair or component swap on a pcb you should find a non-working board to practice on…especially if you have little or no experience. These are delicate little things and if you burn one you will have to repair it. There are repair techniques that I will get into in a future post. So…watch your heat and don’t linger on that pcb! Hit me up if you have any questions..!!!

My shop is located at 1 Executive Dr Unit L Toms River, NJ 08755

Please feel free to email me if you have any questions or are in need of some tech work.

- Monday: 10am - 5pm

- Tuesday: 10am - 5pm

- Wednesday: Closed

- Thursday: 10am - 5pm

- Friday: 10am - 5pm

- Saturday 10am - 2pm. (I am in every other Saturday).

I am also an Eminence, Mercury Magnetics, Mojo Musical Supply dealer.

I do all the tech work myself so you deal directly with me. I am a one man shop and my hours can vary so please contact me to confirm that I will be open.

Email me: billy@300guitars.com

Call or text me: 848-218-0362

Shipping Info for all repair work:

Please ship all repairs to: 1 Executive Dr Unit L Toms River, NJ 08755

I am currently offering all phases of guitar work which includes:

- Set-ups

- Fret dressing

- Re-fretting

- New hand cut custom bone nuts & saddles

- Electronics work

And amplifier work which includes:

- Basic maintenance

- Bias adjustment

- Repairs and restorations

- Modifications

- And more....

Testimonials:

David Nicholas - The 20watt amp is sounding fantastic! Delivered the goods at the gig and I'm finding cool tones all over the place with it. Love the cab w Emenince Tonkerlites too- perfect for my sounds! Makes the 12 string sound like a grand piano!

Peter Lacis - I had an audition for something recently that was all about Led Zeppelin I -- my custom Pennalizer BLEW THE MINDS of the guys I was playing with. They couldn't believe the sounds coming out of that amp. That album was never in my mind when I came up with the idea....so that's yet another testament to the amazing work that you do.

Scott Goldberg - I am very satisfied with the set-up, and the fast turn around. With the "lower" action it feels easier to play. I will definitely spread the word.