Before: Printed circuit boards throughout. I find that pcb’s are more difficult to service and modify. Because of the small size of the components on the board you are limited on parts choices. Mallory 150’s or some boutique PIO caps will not fit. I believe that the carbon film resistors are not helping either especially for plate load resistors. Fortunately there is a solution……

Before: Printed circuit boards throughout. I find that pcb’s are more difficult to service and modify. Because of the small size of the components on the board you are limited on parts choices. Mallory 150’s or some boutique PIO caps will not fit. I believe that the carbon film resistors are not helping either especially for plate load resistors. Fortunately there is a solution……

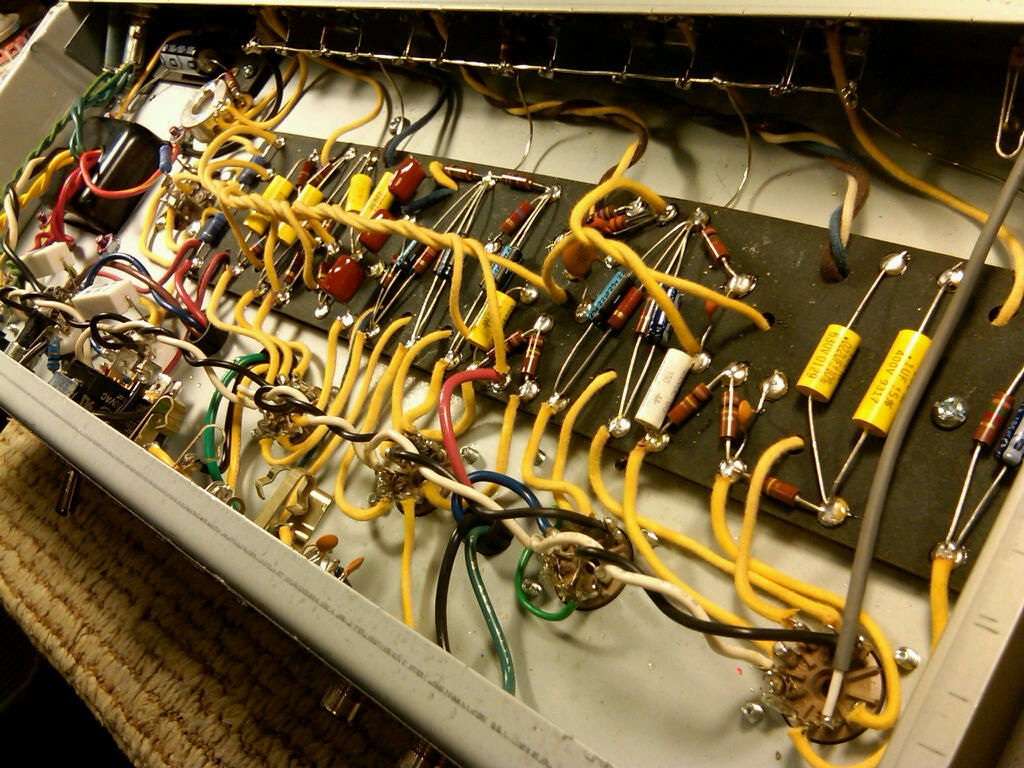

After: The solution is to gut the pcb’s out and hand wire the amp using the old style fiber board material. There is plenty of room and everything (even the old style 4 section can cap) fits nicely. I left the filament wiring alone but basically everything else when out the window. I even swapped the output transformer for one made by Mercury Magnetics with a larger core with 8 and 4 ohm secondary. Now the amp sounds great! Loud and clear with smooth breakup and wonderful dynamics. Using some smaller value bypass caps and the addition of the larger OT the bottom end becomes clearer and more defined. A few other changes were the Paul C mod to the driver section and an Eminence Ragin’ Cajun 10″ speaker which was the finishing touch to the overall sound of the amp. Now this amp really performs its best with awesome tone and dynamics, is much more reliable and gig-worthy, lastly it is much easier to service or tweak. Hand wired!!!

After: The solution is to gut the pcb’s out and hand wire the amp using the old style fiber board material. There is plenty of room and everything (even the old style 4 section can cap) fits nicely. I left the filament wiring alone but basically everything else when out the window. I even swapped the output transformer for one made by Mercury Magnetics with a larger core with 8 and 4 ohm secondary. Now the amp sounds great! Loud and clear with smooth breakup and wonderful dynamics. Using some smaller value bypass caps and the addition of the larger OT the bottom end becomes clearer and more defined. A few other changes were the Paul C mod to the driver section and an Eminence Ragin’ Cajun 10″ speaker which was the finishing touch to the overall sound of the amp. Now this amp really performs its best with awesome tone and dynamics, is much more reliable and gig-worthy, lastly it is much easier to service or tweak. Hand wired!!!