String construction

Depending on the construction of the instrument on which they are used, strings will usually have either a ball or loop at one end to attach the string to the instrument. Strings for some instruments may be wrapped with silk at their ends to protect the string. The color and pattern of the silk can be used to identify the string.

Winding There are several varieties of wound strings.

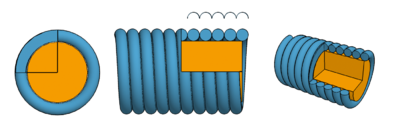

Roundwound

The simplest ones are the roundwound strings. They have a round core inside and round-winding wire, wound in a tight spiral around it. Such strings are usually simple to manufacture and thus are usually the least expensive. There are several drawbacks, however:

- Roundwound strings have a surface profile (the “bumps” of the winding) that causes “squeaking” sounds when the player’s fingers slide over the strings. Whereas some artists use this sound creatively on purpose, this sound is, in general, unwanted.

- Non-flat surface profile also hastens fingerboard and fret wire wear.

- The winding is not secured to the core and can rotate freely around it, especially if the winding is damaged after use. It makes it harder to push down and hold the strings with the fingers, and thus impairs the general playing experience.

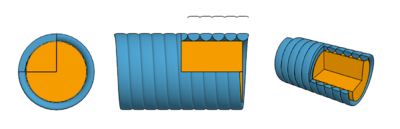

Flatwound

Flatwound strings also have a round core, but the winding wire has a rounded square cross-section. When tightly wound, such strings have a much shallower profile (in cross-section), thus making them more comfortable to play, less damaging for frets / fretboard and producing quieter squeak sounds from fingers sliding along the string. However, players frequently cite that the sound of flatwound strings differs considerably from the sound of roundwound, with less brightness.

Halfwound, ground wound, pressure wound

Halfwound strings, ground wound strings or pressure wound strings are a cross between roundwound and flatwound, providing both the tonal characteristics of roundwound and the lack of squeaking and the playing feel of flatwound. Such strings are usually made by winding round wire around a round core first, then polishing, grinding (thus the name, ground wound) or pressing the exterior part of the winding until it is practically flat.

Note that polishing process removes almost half of winding wire mass, thus, to compensate for it, manufacturers have to use heavier gauge winding wire. In its turn, thicker winding wire lowers frequency of slide squeaking. Depending on sound processing, it can be a good thing (as squeaking becomes less accented and it will be masked out by performed music) or a bad thing (high-pitched squeaks are much easier to detect and filter out when recording).

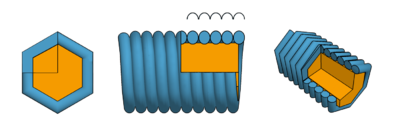

Hexwound

Hexwound strings are composed of regular hexagonal core and a tight (usually round) winding that closely fits a hexagonal shape. It solves the second problem: it secures the winding around the core, so it cannot rotate and slip under the fingers. Sometimes it is cited that hexagonal core improves tones due to closer bond between the core and the winding[3] The drawback is that relatively sharp hexagonal corners are less comfortable for fingers and wear down the fingerboard and fret wire even faster than roundwound strings. Hexwound strings are more commonly used on bass instruments (such as bass guitars).

Gauge

The tone of a string depends on its weight, and, therefore, on its diameter or so-called gauge. Traditionally, diameter is measured in thousandths of an inch. The larger the diameter, the heavier the string is. Heavier strings require more tension for the same pitch and are, as a consequence, harder to press down to the fingerboard. Heavier strings will also produce a louder and thicker tone. (If a fretted instrument is restrung with different string gauges, it may be necessary to adjust the height of the string above the frets, called the “action,” in order to make the instrument easier to play or to avoid the strings buzzing against the frets. The action height of fretless instruments may also be adjusted to suit the string gauge or material, as well as the intended playing style.)

Steel strings for 6-string guitar usually come in the sets of matched strings. Sets are usually referenced either by the gauge of the first string (e.g., 9), or by pair of first and last (e.g., 9-42). Some manufacturers may have slightly different gauge sequences; the sample data below comes from D’Addario string charts for regular, round-wound, nickel-plated strings.

(Note: strings in gray boxes are wound. All others are plain.)

| Name |

1

(e) |

2

(B) |

3

(G) |

4

(D) |

5

(A) |

6

(E) |

| Extra super light (8-38) |

.008 |

.010 |

.015 |

.021 |

.030 |

.038 |

| Extra super light plus (8.5-39) |

.0085 |

.0105 |

.015 |

.022 |

.032 |

.039 |

| Super light (9-42) |

.009 |

.011 |

.016 |

.024 |

.032 |

.042 |

| Super light plus (9.5-44) |

.0095 |

.0115 |

.016 |

.024 |

.034 |

.044 |

| Regular light (10-46) |

.010 |

.013 |

.017 |

.026 |

.036 |

.046 |

| Extra light w/heavy bass (9-46) |

.009 |

.013 |

.021 |

.029 |

.036 |

.046 |

| Medium (11-49) |

.011 |

.014 |

.018 |

.028 |

.038 |

.049 |

| Medium w/wound G string (11-52) |

.011 |

.013 |

.020 |

.030 |

.042 |

.052 |

| Heavy (12-54) |

.012 |

.016 |

.020 |

.032 |

.042 |

.054 |

| Extra heavy (13-56) |

.013 |

.017 |

.026 |

.036 |

.046 |

.056 |

Credit: Wkipedia

To see how guitar string are made visit You Tube for a video clip from the TV show “How It’s Made”.

Here is an in depth page about the origins of the guitar string on the Early Music Index site.

These are the frequencies that guitar strings vibrate: E-82 Hz, A-110 Hz, D-147 Hz, G-196 Hz, B-247 Hz, E 330 Hz.

My shop is located at 1 Executive Dr Unit L Toms River, NJ 08755

Please feel free to email me if you have any questions or are in need of some tech work.

- Monday: 10am - 5pm

- Tuesday: 10am - 5pm

- Wednesday: Closed

- Thursday: 10am - 5pm

- Friday: 10am - 5pm

- Saturday 10am - 2pm. (I am in every other Saturday).

I am also an Eminence, Mercury Magnetics, Mojo Musical Supply dealer.

I do all the tech work myself so you deal directly with me. I am a one man shop and my hours can vary so please contact me to confirm that I will be open.

Email me: billy@300guitars.com

Call or text me: 848-218-0362

Shipping Info for all repair work:

Please ship all repairs to: 1 Executive Dr Unit L Toms River, NJ 08755

I am currently offering all phases of guitar work which includes:

- Set-ups

- Fret dressing

- Re-fretting

- New hand cut custom bone nuts & saddles

- Electronics work

And amplifier work which includes:

- Basic maintenance

- Bias adjustment

- Repairs and restorations

- Modifications

- And more....

Testimonials:

David Nicholas - The 20watt amp is sounding fantastic! Delivered the goods at the gig and I'm finding cool tones all over the place with it. Love the cab w Emenince Tonkerlites too- perfect for my sounds! Makes the 12 string sound like a grand piano!

Peter Lacis - I had an audition for something recently that was all about Led Zeppelin I -- my custom Pennalizer BLEW THE MINDS of the guys I was playing with. They couldn't believe the sounds coming out of that amp. That album was never in my mind when I came up with the idea....so that's yet another testament to the amazing work that you do.

Scott Goldberg - I am very satisfied with the set-up, and the fast turn around. With the "lower" action it feels easier to play. I will definitely spread the word.